About CNC

CNC (Computer Numerical Control) is a technology that has revolutionized the manufacturing industry. It has replaced manual operations with automated computer-controlled systems that produce accurate, consistent, and repeatable results.

CNC technology works by taking a design or blueprint for a part or product and translating it into a set of instructions that a machine can follow. These instructions are called G-code, and they tell the machine what to do, where to move, and how fast to go.

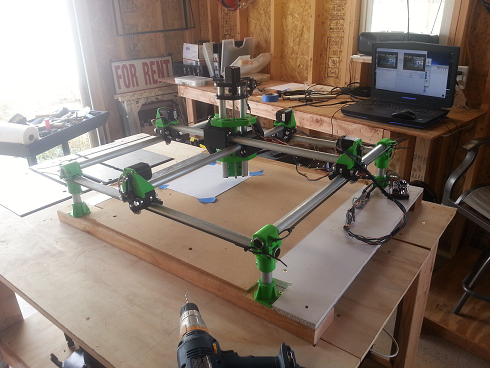

CNC machines come in various forms, including milling machines, lathes, routers, and plasma cutters. They all operate in similar ways, with a computer-controlled spindle or cutting tool that moves in three or more axes to shape the material being worked on. The material can be metal, plastic, wood, or any other material that can be cut or shaped with a machine.

The benefits of CNC technology are numerous. First and foremost, it improves accuracy and precision. CNC machines can make the same part repeatedly, with the exact same dimensions and tolerances, eliminating the variability that comes with manual operations. CNC machines are also capable of producing complex shapes and designs that would be impossible or difficult to achieve with manual methods.

Another advantage of CNC technology is increased efficiency. CNC machines can work faster and longer than humans, which means more parts can be produced in less time. They also require less supervision, freeing up human resources for other tasks.

CNC machines also offer flexibility in design and production. Because they are controlled by computer software, changes can be made quickly and easily, without the need to retool or start from scratch. This allows manufacturers to respond to changes in demand or design quickly and efficiently.

Finally, CNC technology can improve safety in the workplace. Because the machines are controlled by computers, there is less need for human operators to be in close proximity to the cutting tool or material. This reduces the risk of accidents and injuries, making the workplace safer for everyone.

In conclusion, CNC technology has transformed the manufacturing industry by improving accuracy, efficiency, flexibility, and safety. As technology continues to advance, we can expect to see even more impressive advancements in the world of CNC machining.

This new CNC should be alot of fun.